What is ETFE surface material?

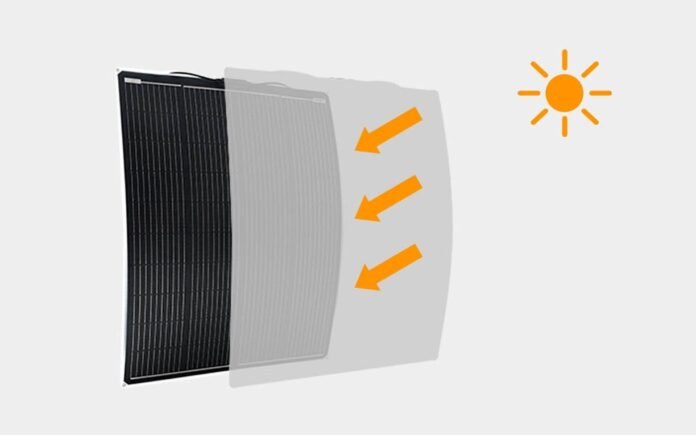

ETFE (ethylene tetrafluoroethylene copolymer) is a fluorine-containing plastic that can be used as a protective coating for flexible solar panels to improve their energy conversion efficiency and durability. etfe surface materials have the following characteristics:

- High light transmission: ETFE almost completely transmits UV light, allowing more solar energy to reach the solar cell, and also allows different translucency and colors to be designed as needed.

- High fire resistance: ETFE can be used in the temperature range of -200°C to 150°C and is not easy to burn or melt.

- High chemical resistance: ETFE is almost impervious to any chemical substances and can protect flexible solar panels from acids, alkalis, solvents, oils, etc.

- High dirt resistance: ETFE has non-adhesive surface, dust and dirt can be easily washed away by rain, reducing the cost of cleaning and maintenance.

- High abrasion resistance: ETFE has high tensile strength, impact strength and tear resistance, which can resist mechanical stress and external forces.

The difference between ETFE surface material and other surface materials

There are two main types of surface materials for flexible solar panels: fluorinated plastics and non-fluorinated plastics. Fluorine-containing plastics include PTFE, PFA, FEP, ETFE, ECTFE, etc., while non-fluorine-containing plastics include PET, PVC, etc. The differences between them are mainly reflected in the following aspects [^2^][2]:

- Temperature resistance: The temperature resistance of fluorinated plastics is generally higher than that of non-fluorinated plastics, among which the maximum use temperature of PTFE, PFA and FEP are above 200℃, while the maximum use temperature of PET and PVC is generally below 100℃.

- Chemical resistance: The chemical resistance of fluorinated plastics is generally higher than that of non-fluorinated plastics, among which PTFE, PFA and FEP are almost immune to any drugs, while PET and PVC are sensitive to acids, alkalis and solvents.

- Stain resistance: The stain resistance of fluorinated plastics is generally higher than that of non-fluorinated plastics, among which PTFE, PFA, FEP have non-adhesive surface and dust and dirt can be easily washed away by rain, while PET and PVC are easy to absorb dust and dirt and need regular cleaning.

- Wear resistance: The wear resistance of fluorinated plastics is generally higher than that of non-fluorinated plastics, of which PTFE, PFA, FEP have lower coefficient of friction and better wear resistance, while PET, PVC are easy to be scratched or torn.

In summary, the use of ETFE surface material in flexible solar panels has obvious advantages, which can provide higher energy conversion efficiency and longer service life compared to other surface materials.

Application examples of ETFE surface materials on flexible solar panels

The use of ETFE surface materials in flexible solar panels has become more and more widespread, and it can be adapted to a variety of shapes and designs of surfaces, allowing for more innovation and functionality. The following are some examples of flexible solar panel applications using ETFE surface materials:

- Outdoor camping: ETFE flexible solar panels can be used as camping supplies to provide charging for cell phones, tablets and other devices. They can be easily folded or rolled up for portability and storage. They can also withstand harsh weather conditions such as rain, snow, wind, etc.

- RV Roofs: ETFE flexible solar panels can be used as part of the RV roof to provide power to the interior of the RV. They can be customized to fit the curvature of the RV roof for optimal solar energy capture. They can also prevent the RV roof from overheating or overcooling.

- Architectural curtain walls: ETFE flexible solar panels can be used as elements of architectural curtain walls to provide aesthetics and energy savings to buildings. They can be designed to match the building’s appearance and style to achieve different translucencies and colors. They can also reduce a building’s dependence on conventional energy sources.

Summing up

ETFE surface material is an excellent flexible solar panels coating material with high light transmission, high fire resistance, high chemical resistance, high stain resistance and high abrasion resistance. Compared with other surface materials, it can provide higher energy conversion efficiency and longer service life. ETFE surface material on flexible solar panel is also becoming more diverse and innovative in its application, and it can adapt to various shapes and designs of surfaces for more functionality and aesthetics.