Plumbers can now offer their customers a no-dig, no-mess pipe relining solution for stormwater and sewage pipe problems thanks to new technology. Pipes had to be dug up first, which took a long time and was quite expensive. Pipe relining has no effect on the landscape or concrete roads. In this case, the The Relining Company is the finest option.

What is the process of relining pipework?

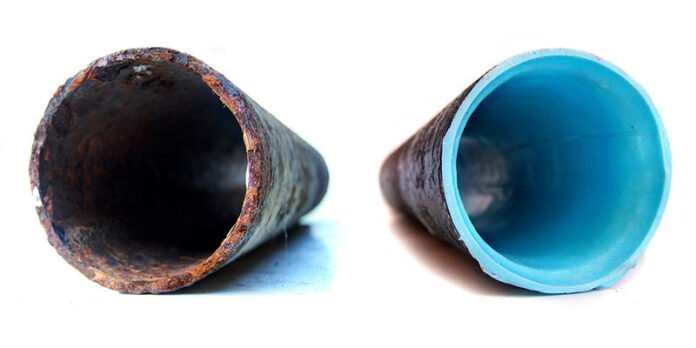

Relining a pipe is replacing an old, damaged pipe with a new one. Depending on the amount of the tree root invasion, complete networks or small sections of pipe can be restored quickly and efficiently.

The first step in determining whether pipe relining is acceptable is to clean the area to be relined with a high-pressure water jetter to remove any debris and tree roots. A drain cam is then inserted to determine the degree of the pipe damage and whether it can be relined. Once the plumber gets this knowledge, he or she will be able to spot the issue areas and give you an estimate before starting the relining. Relining can be done on entire lengths of pipe up to 70 meters.

- A flexible cloth liner is trimmed to size depending on the size of the reline area.

- The liner is then resin-impregnated and connected to a lengthy rubber pipe via an air hose.

- It’s inserted into the pipe and then yanked or pushed into place using ropes or pushrods. During this time, a camera is in the line to ensure the liner is correctly put.

- After determining the right installation, the air hose is used to inflate the long pipe, allowing the liner to develop to its full size inside the pipe.

- The resin-coated liner is then allowed to dry for anywhere between 1.5 and 6 hours.

- The rubber tube is deflated and withdrawn after the resin has dried, leaving a new faultless pipe inside the old broken one.

- The camera is reinserted to verify and confirm the work’s completion.

- If necessary, a robotic cutter can be employed to trim the liner or reopen junction branches.

There are several advantages to no-dig pipe relining

- Tree roots will be able to find their way back into a pipe using the dig-up method thanks to the flexible connection pipe between the new and old pipes. Tree roots are unable to penetrate a relined section of the pipe.

- It’s not only faster and easier than the old “dig up” method, but it also generates a much smoother surface, making it a great substitute.

- It creates the least amount of disruption and takes the least amount of time and money compared to more traditional methods.

For example, to dig out a pipe under a bathroom floor, the tiles and concrete would have to be ripped up. Reaching the pipe would necessitate removing fixtures and jackhammering through the floor. It could be a small part of the entire bathroom floor, depending on the size of the pipe that needs to be replaced. They would need to be wrapped in order to avoid causing damage to the walls. Along with the actual repair, the floor would need to be reconfigured and re-tiled. It’s possible that this treatment will take up to two weeks, if not more. Being unable to use the bathroom for two weeks is not great.

Conclusion:- Relining takes a day or less and is straightforward to do with little mess and hassle, not to mention the labor savings!