When you’re in the business of producing parts, there are two important factors to consider: quality and cost. If you’re producing parts that will be used in machining aluminum, it’s even more important than usual to have an effective way to control both quality and cost so you can stay competitive on the market.

One great way to find an effective balance between cost and quality when machining aluminum is through using an experienced supplier of CNC machining services who uses the latest technology to get your job done quickly and affordably while still meeting your high standards of quality.

Manufacturing Process

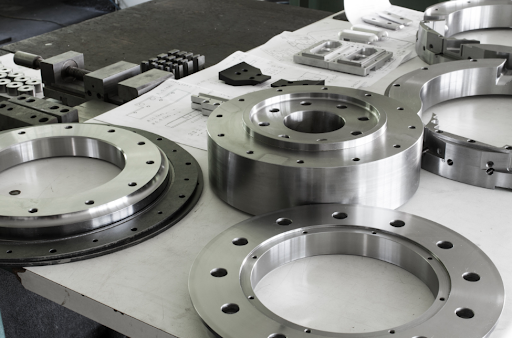

Aluminum is machined using a process called CNC (computer numerical control) machining. This method allows parts to be accurately milled to accurate tolerances and made from any type of aluminum. Tooling plate, plate, extrusions, castings and forgings can all be accurately milled with a CNC router. Milling services are provided for a broad range of industries including automotive, aerospace, and architectural and construction as well as woodworking and food service industries.

We also provide milling services for anodized aluminum, which includes black anodizing, bright aluminum anodizing and natural aluminum anodizing. Aluminum milling is performed on both large production jobs and smaller one-off projects to meet your needs. We have over 25 years of experience in manufacturing processes that include: wire EDM, laser cutting, waterjet cutting and precision grinding & polishing.

Advantages of Aluminum CNC Machining

Precision Machined Components, Cost Saving and Time Efficient :> ALUMINUM CNC MACHINING SERVICES: YIJIN Hardware is an aluminum machining parts supplier specialized in providing customers with precision machined components, both cast aluminum and extruded aluminum (profile extrusions), according to their specifications. The objective is to help customers realize better performance while keeping cost savings and time efficiency in mind.

The challenges in aluminum cnc machining

Aluminum is a relatively soft metal, making it easy to damage while machining. This can result in ‘micro-chipping’, which is an anomaly that forms on your part as a result of small chips being left behind during machining.

This has two main impacts on your final product: First, micro-chipping looks bad and compromises quality. Second, chipped areas degrade and weaken your part over time—not what you want to happen when you use aluminum cnc machined parts in your products.

The process itself can cause problems with micro-chipping too: Because aluminum is so soft and easily damaged, it’s best to machine aluminum with a high speed and low force method—particularly for larger parts. However, smaller parts can be successfully milled at slower speeds. In either case, avoid cutting aluminum with tools like saws or drill bits because they tend to leave sharp edges that are prone to chipping. Also avoid tools that leave burrs and rough surfaces because these create weak points in your aluminum cnc machined parts.

Finally, don’t forget about post-machining operations like cleaning and deburring; these will help you remove any leftover debris from your part after milling or drilling operations are complete.

When done properly, these steps should help prevent micro-chipping issues before they start! Title: Aluminum CNC Machining Services Aluminum is one of those metals that seems simple enough until you try working with it yourself—then everything changes! While aluminum isn’t necessarily difficult to work with, there are some important things to know if you’re going to do aluminum cnc machining.

Here’s a list of some tips we’ve gathered along our journey that we hope will make things easier for you:

How to Choose An Aluminum CNC Machine:

The first step in doing aluminum cnc machining is choosing your machine. Your choice here will depend largely on how much material you need to cut through (and how thick) and how quickly you need it done (the faster machines mean higher costs). Choosing An Aluminum CNC Cutter: Once you’ve chosen your machine, think about cutter selection.For More Information Visit Now: https://yijinsolution.com/brass-machining/